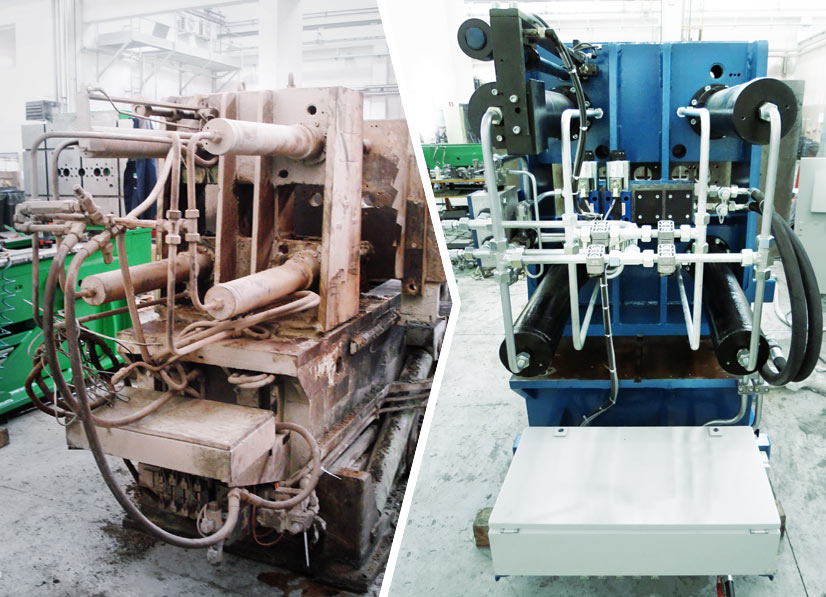

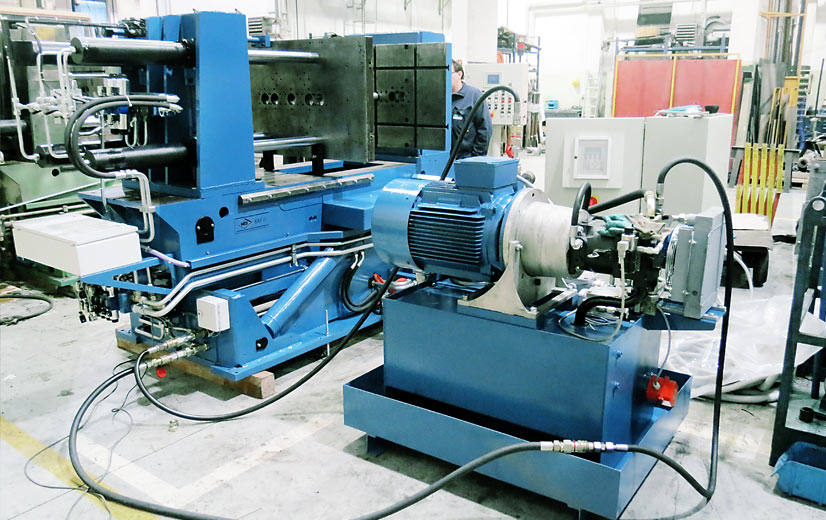

Design – machine frame

- Machine frame repairs (various cracks and unevenness)

- Remakes and upgrades

- Change of bearings

- Sandblasting and paintinge

Hydraulic equipment

- Hydraulic equipment can be modernized in order to improve the reliability and to lengthen the life time

- Repair and modernization of the hydraulic aggregate (pump, pump control, filter in the return line and the secondary circuit, temperature and fluid level control)

- Cylinder repair (seal, piston rod, cylinder tube)

- Replacement or the repair of the steel installation

- Replacement of the flexible tubes

- Installation of thermal protection on the exposed flexible tube

|

Electric equipment and steering

- Modernization of the electrical equipment

- Control system modernization or replacement

- Modernization of the sensor system and safety elements

- Improvement of modification of the software according to customer specifications

Gas equipment

- Renovation and modernization of the gas equipment for moulds

- Renovation and modernization of the existing installation from the connection to the gas circuit to the burners on the machine

Cooling cabinets

- Manufacturing of cooling circles for air mould cooling to customer requirements

- Control of the cooling time and the air flow through software

Casting machine protection fence

- Manufacturing of the casting machine protecting fence according to existing guidelines

- When casting with robots there will be automatic doors installed

|